40ft Mobile Filling Station (40,000 Liters-60,000 Liters)

- Description

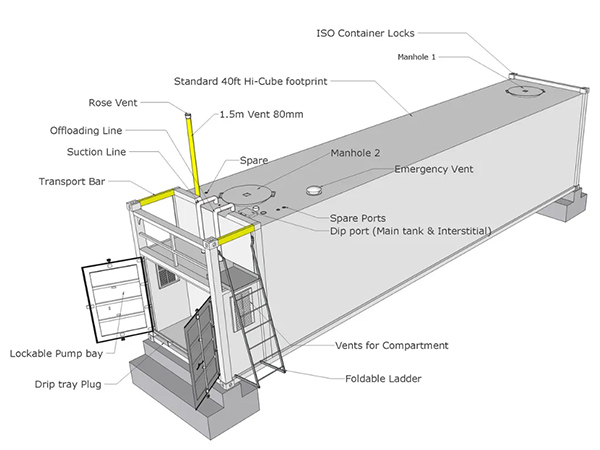

The 40ft Mobile Filling Station diesel storage tank is a high volume self bunded tank with a safe fill capacity of 45000 Litres. The 40ft Mobile Filling Station is used in multiple roles by our customers for high volume applications. An isolated pump bay has lockable space for pumps, filtration, offloading AND fuel management, all factory fitted options.

Mobile fuel station is for the distribution of diesel and gasoline with tanks of variable capacity. It is composed of a container, divided into two main compartments, compartment for fuel tanks and compartment for pump and dispenser, and also provided with optional generator.

Specification

| S.No | Configuration | Specification |

| 1 | Fuel storage tank | One single wall or double walled tank, capacity 40,000 liters ~ 60,000 liters. |

| 2 | Container | A 40ft container includes fuel storage tank location and operation compartment. |

| 3 | Fuel dispenser | 1 or 2 dispenser, each with 1 or 2 filling nozzle. DN40 fuel outlet pipe, equipped with maintenance protection device. |

| 4 | Level gauge | Sight glass level gauge or electric level gauge |

| 5 | Electric system | Power control box and wire |

| 6 | Light system | Explosion-proof light |

| 7 | Safe system | One vent cap, Electrostatic grounding box Suspended fire extinguisher |

| 8 | Painting | The equipment is polished, derusted and degreased. With external three coats of painting. |

| 9 | Overall dimension | 12192mm*2438mm*2591mm (or 2896mm) |

Introduction To Parts

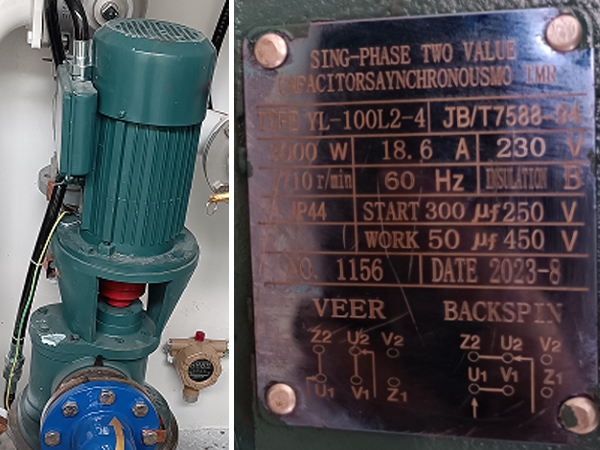

Transfer Pump (Inlet & Outlet Pump):

The pump is for fuel inlet and outlet. There are optional flow rate of pump 10m3/h, 20m3/h, 25m3/h and 30m3/h. The pump is vertical type which can save more space in pump bay.

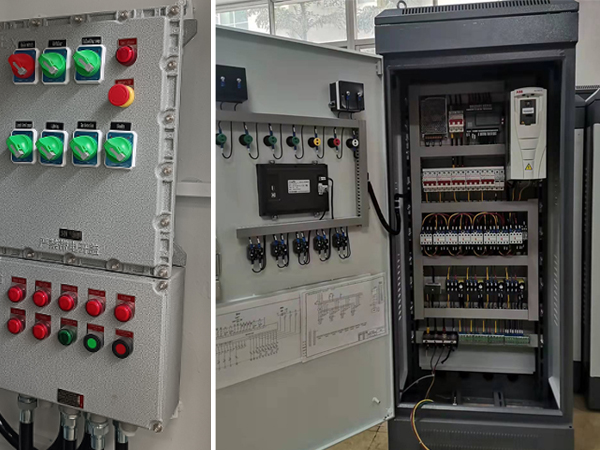

Electric Power Control Cabinet:

One explosion-proof power distribution cabinet for 110V, 220V, 240V or 380V electric. And it is combined with electricity control switch and indicating lights. All functions marked in English.

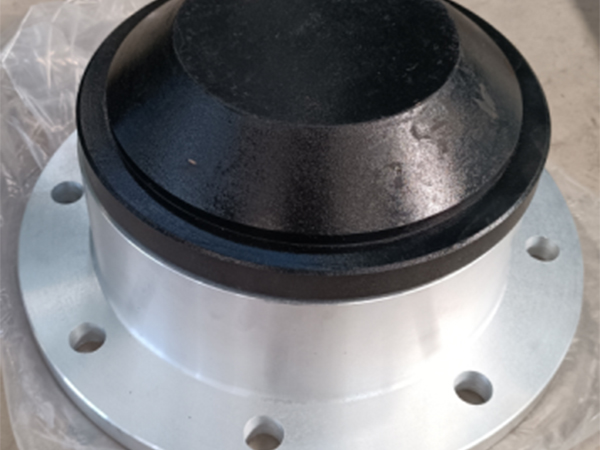

Manhole Cover:

The manhole cover is 600mm in diameter, which is used for maintenance of tank. Manhole cover is installed on top of the tank. It is usually combined with an emergency vent valve on manhole cover.

Emergency vent valve:

When tank internal pressure is too high and the normal venting valve could not reduce the pressure effectively, the emergency pressure relief device will explode to reduce the pressure. Different volume of tanks have different diameter of emergency vent valves.

Level Gauge:

There are three types of level gauge for option: Magnetic float sight level gauge, Instrument type level gauge and Electric level gauge. The level gauge indicates the height of fuel level in tank. And electric level gauge has a screen showing fuel volume and temperature, and with functions of high and low level alarm.

Protecting the appearance of the oil dispenser:

Keep the surface of the oil dispenser smooth and clean regularly. In environments with corrosive gases, such as seaside areas, the surface of the oil machine needs to be cleaned more frequently. Under normal circumstances, it can be cleaned with detergent and soapy water, and then rinsed with water. If hard water is used for cleaning, wipe dry with a soft cloth to prevent water spots from forming. For stains such as grease, oil fingerprints and smoke that cannot be removed with soap and detergents, a cleaner with stronger cleaning power must be used (do not use ordinary steel wool, because iron powder will adhere to the surface of the dispenser and cause corrosion. ). When choosing a cleaning agent, be aware that any compound cleaning powder containing abrasives will wear down the surface of the oil machine. When using, apply in the direction of the metal polishing line and do not cross it. After cleaning, it is recommended to use wax protection to extend the cleaning time interval.

- WhatsApp

- E-MailE-Mail:shengdingtank@126.com

- WeChatWeChat:15254863111