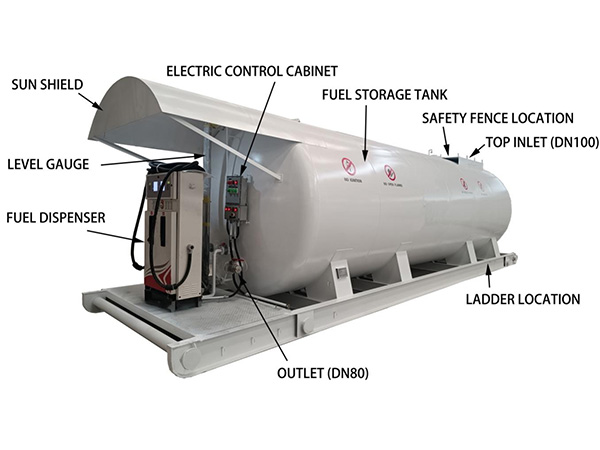

Skid-mounted fuel station

- Description

A skid-mounted gas station is a refueling device used by an enterprise. The internal tank is filled with barrier explosion-proof materials, which are a kind of mesh material composed of special aluminum alloys. The barrier explosion-proof technology transformation is to fill the barrier explosion-proof materials (barrier explosion-proof materials are a kind of mesh material composed of special aluminum alloys) in a certain density in the oil tanks storing flammable and explosive liquids. When encountering open flames, static electricity, impacts, lightning strikes, gunshots, welding, and accidental violent collisions, no explosion accidents will occur. It has the characteristics of fireproof and explosion-proof, safety and environmental protection, small footprint, and easy relocation. The product is widely used in large construction sites such as logistics parks, ports, docks, airports, mines, and internal gas stations of enterprises.

Technical Features

--- Fuel tanks of variable capacity, for diesel or petrol, also with option both diesel and petrol in one station.

--- Explosion-proof type to ensure safety.

--- Fuel loading system to load from fuel tank truck.

--- Top lockable hatches to get access to the manholes of tanks and refuel from above.

--- Static grounding

--- Stainless filters

--- Optional generator to supply electricity power

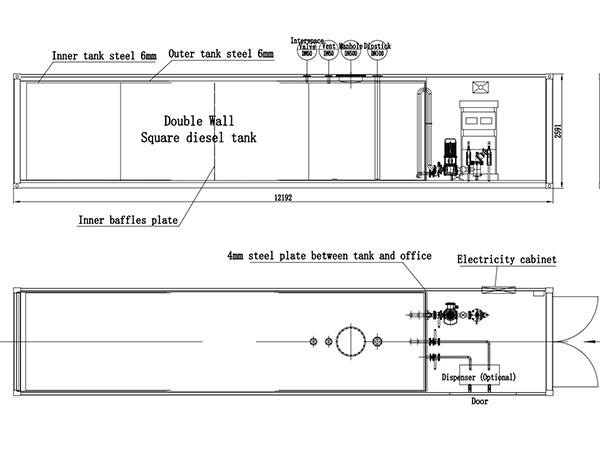

Specification

| 1 | Tank Capacity | 5,000 liters ~ 60,000 Liters |

| 2 | Storage | Diesel or gasoline |

| 3 | Tank Type | Single wall or double walled horizontal cylindrical tank |

| 4 | Tank inside diameter | 1,600mm ~ 2,800mm |

| 5 | Tank inside length | 2,000mm ~ 10,500mm |

| 6 | Overall dimension | Length 3,500mm ~ 12,500mm width 1,620mm ~ 2,900mm height 1,950mm ~ 3,400mm |

| 7 | Tank Steel | Carbon steel Q235B, tank wall thickness 6mm, 8mm or 10mm |

| 8 | Dispenser | One diesel dispenser, 220V, 50HZ(Optional 380V or other voltage) |

| 9 | Electric | Electricity control cabinet Static groundings |

| 8 | Level gauge | One side installed level gauge. |

| 9 | Surface treatment | Painting outside |

| 8 | Accessories | 1 external ladder, 1 internal ladder, One DN80 inlet One DN40 outlet for dispenser Manhole 4 lifting lugs Vent valve on top |

Filling Operation

(1) Firstly, check the hoses and filling nozzles on position. Open the valves between filling dispenser and storage tank.

(2) Turn on buttons for electricity power supply.

(3) After selecting the filling method and amount on the keyboard, take filling gun from the dispenser, and the dispenser will return to zero and start to refuel.

(4) Insert the filling gun into the liquid receiving container and use the spring on the gun nozzle to hang it firmly with the liquid receiving container. When the fuel foam or fuel rises to the filling gun nozzle, the filling gun will automatically close (note: the filling gun may not automatically close due to failure or insufficient pressure of small flow, resulting in liquid overflow).

(5) After filling the fuel, put the filling gun back into the dispenser and press the lifting switch. At this time, the display screen shows the number of liters filled and the amount.

(6) When refueling, fuel splashing should be avoided, especially not splashing onto high-temperature engines and exhaust pipes.

(7) If there is any liquid overflow during filling, the filling gun or dispenser should be immediately turned off and the spilled liquid should be disposed of.

(8) After filling, the filling gun should be immediately withdrawn from the receiving container to prevent accidents caused by vehicle dragging.

(9) The rubber hose of the refueling machine should be placed in a safe position to prevent accidents from being crushed by vehicles.

(10) When the vehicle enters the refueling area, the refueling worker should guide the vehicle into the refueling position and stop steadily, and remind the driver to turn off the engine before opening the fuel tank cap for refueling. After completing procedures such as refueling and settlement, vehicles should be guided to leave the refueling area in a timely manner.

(11) When using the refueling machine, the refueling operator should pay attention to whether the machine is operating normally, including whether there are leaks, abnormal noise, abnormal odors, etc. If there are any abnormalities, immediately take measures such as shutdown, power outage, and reporting.

(12) Non explosion-proof electrical equipment such as cassette recorders, fans, extension cords, and other debris shall not be placed on the filling stattion.

(13) It is prohibited to add fuel to insulated containers.

(14) The refueling operation on non self-service refueling machines should be operated by refueling personnel and not by customers themselves.

(15). Smoking and the use of mobile phones are strictly prohibited in the station.

(16) The refueling personnel must wear anti-static clothing on duty.

(17) When there is lightning in the refueling area, refueling operations should be stopped and personnel should take protective measures.

(18) Smoking and fire are strictly prohibited within 30 meters around the filling station.

(19) According to fire protection requirements, must be equipped with a 35 kg dry powder fire extinguisher, 4 fire blankets, and 2m3 of sand.

- WhatsApp

- E-MailE-Mail:shengdingtank@126.com

- WeChatWeChat:15254863111